Table Of Content

In the early stages, when you’re still getting to know your users and validate potential solutions, focus on deploying user interviews, surveys, and feedback tools. You’ll use low-fidelity prototypes at this stage (like paper prototypes and basic mockups) to give participants a general sense of your product design ideas. Making design verification and validation mistakes often ends in unfavorable outcomes such as product approval delays. Enlisting the help of medical device quality consulting experts to ensure the entire process goes smoothly leads to faster time to market and fewer roadblocks along the way.

Branded F&B Digital Experience

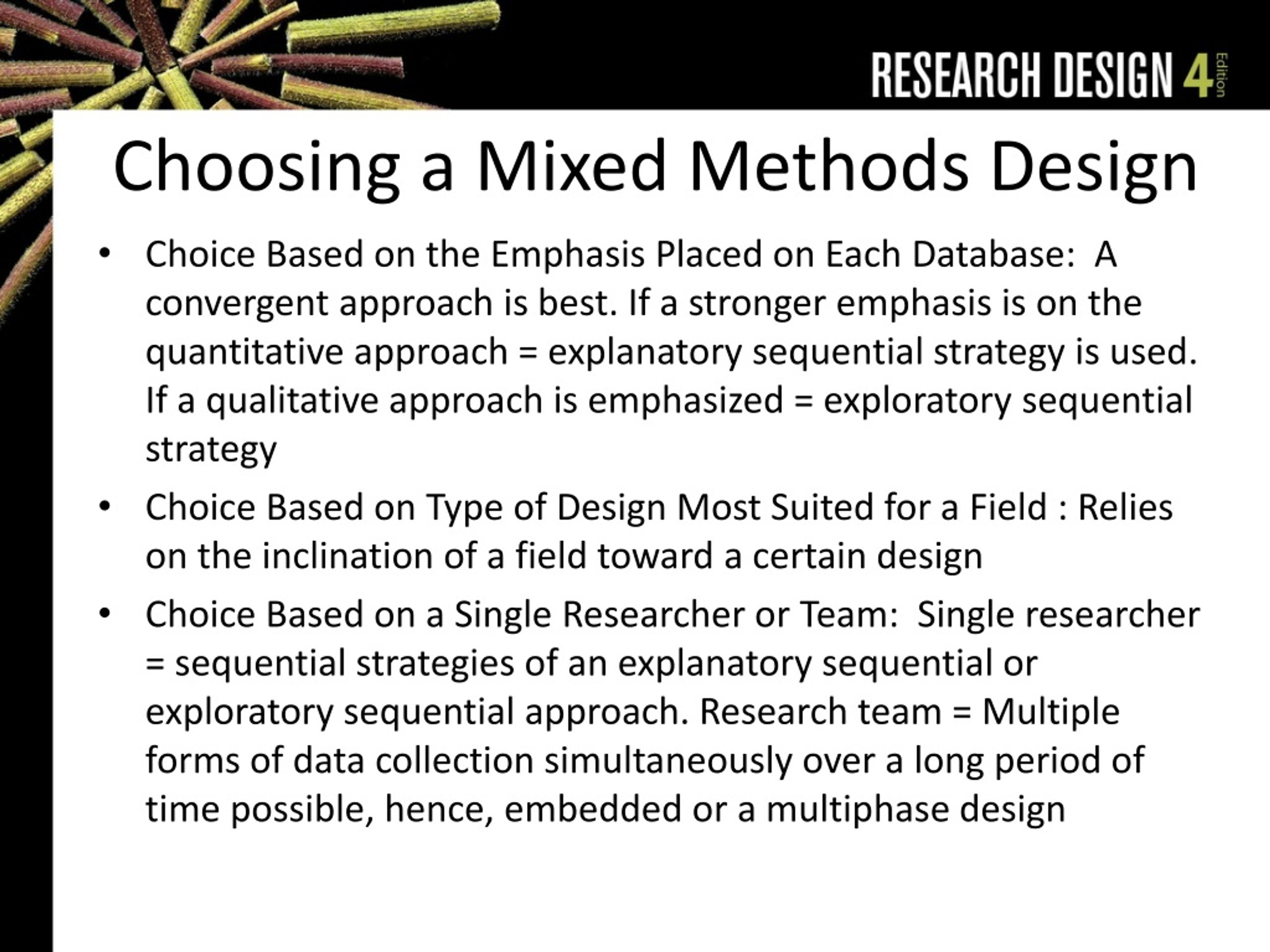

Design verification focuses on confirming that the design outputs of a medical device meet the specified design inputs. It involves a systematic and objective evaluation of the device’s design to ensure that it fulfills the intended requirements. This process encompasses various activities such as testing, analysis, inspections, and reviews, which aim to validate the design’s functionality, performance, safety, and regulatory compliance. The best product design testing methods depend on your company type, goals, and your stage of product development.

Stop guessing about your digital experience with LogRocket

Create the staples of your brand with graphic design ideas for your logo and a detailed brand book to support further steps. Our design team created bespoke logo, brand book and web design as Dognomics launched their DNA test in the U.S. Our services for luxury realters NewDevRev included logo design, brand strategy and website design. Once your product passes the necessary tests, you can also send some of the samples as beta units to potential customers and expert reviewers for a first-hand opinion of your products. Next, they use the existing components to produce prototypes with the expected vital functionalities. They then integrate the prototype with the proof of concept, PoC, to reach a fixed scope that your product can achieve at the end of the EVT.

Timeframe

In this white paper, learn how to combine rapid tooling with traditional manufacturing processes like injection molding, thermoforming, or casting. Download our white paper for guidelines for using 3D printed molds in the injection molding process to lower costs and lead time and see real-life case studies with Braskem, Holimaker, and Novus Applications. The output of this verification review is often recorded in a Statement of Compliance document.

It’s important to get feedback from a designer or a user who understands your product so they can provide valuable and actionable information. Every designer has an innate mindset that often pushes them to judge designs built by others. It simply involves asking a designer colleague, partner, or friend to analyse your design. You’ll be surprised at how effective this method is, especially in generating new ideas.

Building your traceability as you go will keep holes from developing unnoticed. Few things are harder to recover from than discovering you’ve missed critical requirements, risk-mitigating features, or essential tests just when you think your development work is complete. Here are tips to make sure you get the most out of your design verification & validation. Test plan, test cases, test execution records, and test results should be documented and maintained as a part of design records. Validation, in its entirety, is not the result of a single activity, but the collection of results from all validation activities. Includes testing of production equivalent units under real-use conditions.

Tips for Better Design Verification & Validation

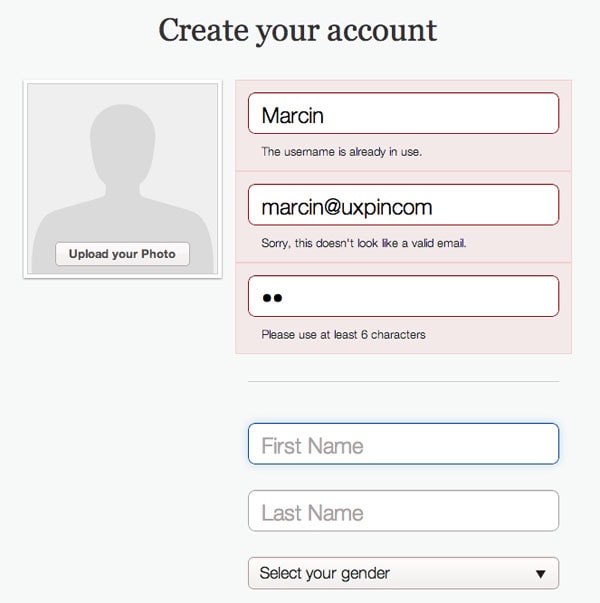

With first-click testing methods, teams observe users to see where they click first on an interface when trying to complete certain tasks. For electronic products, high-end ‘hot stake’ PCBs are developed using industrial processes. You can find the FDA’s definitions for both design validation and verification in 21 CFR Part 820.3. These tools leverage cutting-edge AI to enhance creativity, ensure error-free grammar, and streamline content production. Usability testing usually entails having interviews with at least 5 users to measure design's performance.

Four New MacBooks on Schedule for Launch in 2024 - MacRumors

Four New MacBooks on Schedule for Launch in 2024.

Posted: Mon, 16 Oct 2023 07:00:00 GMT [source]

Design Verification

He specializes in technical guidance and product development efficiency for global organizations. An expert in software development, he is dedicated to helping customers drive quality product strategy. See how Helix ALM can accelerate medical device development without compromising product quality, safety, or compliance.

Bringing A New Brand Into The World

Finally, system verification tests validate the overall functionality, performance, and interoperability of the entire system, ensuring that it meets the defined requirements and specifications. During the design process, design verification plays a crucial role in ensuring that the design outputs align with the design inputs. As previously discussed in the definition section, design verification involves the identification of specific requirements that pertain to the functionality, performance, usability, and safety of the device. This verification process aims to demonstrate that each of these identified requirements is effectively addressed.

Their Customer Happiness Index (CHI) score saw a 25 percent increase after the changes. Visa’s team leveraged data analytics tools to measure performance and run more frequent experiments to continuously iterate and design a better user experience for their users. Often, we can use an accessibility checklist to verify that certain criteria have been met. You can also do accessibility testing with users to observe how a product might be used in a real setting, perhaps with assistive technologies like a screen reader. Both methods of verification are necessary to ensure that the product is designed and built to be accessible. Maybe testing during the verification and validation stages reveal issues that can only be fixed with a change to the design.

Hallway testing is pretty much yanking anyone you can lay your eyes on and having them interact with your design to gather feedback. Ideally, that “anyone” should be a potential user of the product you’re testing so that Lucy from accounting doesn’t review an app for ER nurses. LogRocket lets you replay users' product experiences to visualize struggle, see issues affecting adoption, and combine qualitative and quantitative data so you can create amazing digital experiences.

The production validation test (PVT) is the final phase before mass production starts. Hard tooling is fixed, meaning that no more changes to either the product design or production molds can be made. Jigs, fixtures, and test benches must be in place and validated for the production pilot (PP) to commence. Efforts made in this stage are directed towards optimizing and stabilizing the production and assembly lines in terms of line speed, operator expertise, scrap rate, and daily yield. However, it brings along enormous risks to invest PVT-scale resources so soon, and cutting corners like this is hardly, if ever, advised.

Being inspired by Khoros’ community homepage design, Visa’s UX team decided to highlight their forum upfront on the community page. With this change, it would be easy for developers to engage with the Visa Developer team without getting lost. Validating assumptions early on can give designers the answers to make better-informed decisions and steer them down the right path.

Understand how to define both a UX mission and UX vision in order to create team alignment and accomplish your product goals. Do not wait until the design is complete to conduct your design evaluation as this can lead to costly redesigns! Make sure to integrate it early in the process and iterate where possible leading up to the completion of your first design draft. UX professionals at Slack gathered user feedback and had their interface redone to include a slicker navigation bar as well as features like dark mode. Make sure to only collect data that are relevant to your predefined goals.

Design validation happens late in product development, but it’s based on the first step in the design controls process—defining your user needs. And as soon as you have your user needs, you can begin planning how you’ll validate them later on. There’s no need to wait until you reach the validation step to start thinking about it. While these may seem like very similar processes, you absolutely must go through both design verification and validation.

At the early stages, when you’re still trying to discover more about your users and validate potential solutions, you should focus on deploying user interviews, surveys, and feedback tools. It took the IDEO design team 80 foam models just to get the shape of the first ergonomic computer mouse right for Microsoft back in 1987. Desk checking is a great way for designers and developers to verify that the product is implemented according to the design specifications. While this is an internal method of verification, external methods like A/B testing and usability testing gather data from users to verify the effectiveness and overall usability of the solution.

No comments:

Post a Comment